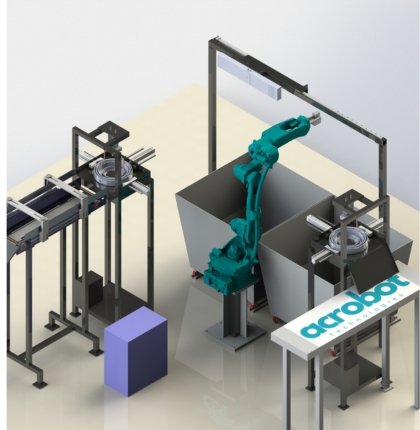

End Of Line Inspection Machine

Where Our Technologies Perform

Specifications

-

Machine Type

Automatic or semi-automatic inspection machine configurable as per application.

-

Inspection Methods

Supports visual, dimensional, functional, and sensor-based inspection.

-

Inspection Accuracy

High inspection accuracy using cameras, sensors, and measurement tools.

-

Inspection Speed

Optimized inspection cycle time for high-throughput production lines.

-

Vision & Sensor System

Integrated vision cameras, laser sensors, and proximity sensors.

-

Control System

PLC-based control system with HMI touch screen interface.

-

Data Logging & Traceability

Stores inspection results with product ID, date, and time for traceability.

-

Pass/Fail Sorting

Automatic segregation of OK and NG parts based on inspection results.

-

Safety Features

Emergency stop, safety interlocks, and protective guarding.

-

System Integration

Compatible with conveyors, robots, MES, and SCADA systems.

Where Our Technologies Perform

Benefits

- Improves product quality with accurate and repeatable inspection

- Reduces manual inspection errors and labor costs

- Speeds up inspection cycles for higher throughput

- Detects defects early to reduce scrap and rework

- Supports traceability with automated data capture

- Integrates seamlessly with automated production lines

Acrobot Technologies

Why Choose Inspection Machine?

Transform Your Factory with Smart Robotic Cobot Solutions

Related Products

Get in Touch with Our Automation Experts

Have a project in mind? Let’s turn your ideas into intelligent automation.

Quick Inquiry