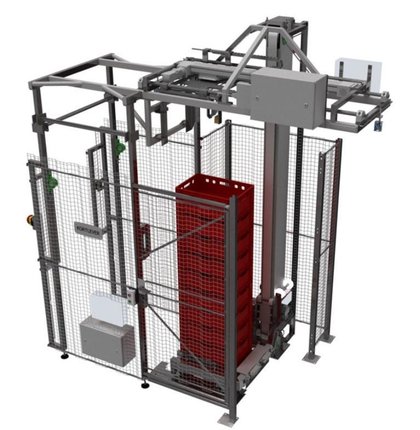

Crate Stacker & De-stacker

Our Crate Stacker & Destacker Solution automates the stacking and de-stacking of crates for faster, safer, and more efficient material handling. Designed for warehouses, industrial facilities, and production lines, this system improves throughput, optimizes storage flow, and reduces manual labor while ensuring smooth and reliable crate transitions.

Where Our Technologies Perform

Applications

-

Crate Stacking

Automated stacking of empty or loaded crates for storage or dispatch preparation.

-

Crate Destacking

Efficient removal of crates from stacks for processing or line feeding.

-

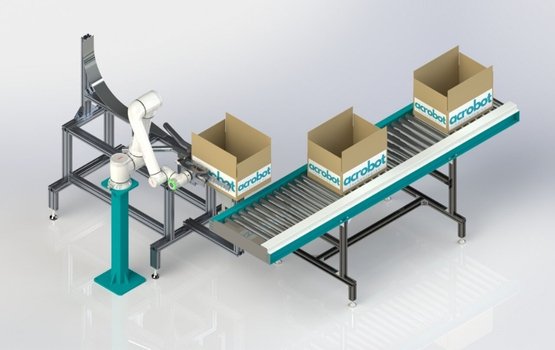

Conveyor Integration

Seamless connection with conveyor systems for continuous crate flow.

-

Mixed Crate Handling

Supports varied crate sizes and types within the same workflow.

-

Packing & Unpacking Support

Feeds crates into packing or unpacking stations with precision and timing.

-

Warehouse Inventory Flow

Automated crate transitions for efficient warehouse stock rotation.

Where Our Technologies Perform

Benefits

- Increases throughput with fast and reliable crate stacking

- Reduces manual labor and physical strain on workers

- Improves warehouse organization and storage flow

- Supports diverse crate formats and sizes

- Enhances safety by automating repetitive material handling

- Integrates smoothly with conveyors and logistics systems

Acrobot Technologies

Why Choose Our Crate Stacker & De-stacker?

Our Crate Stacker & Destacker Solution delivers efficient and reliable automation for crate material handling in warehouses and production facilities. Engineered for flexibility and high throughput, the system handles multiple crate types and integrates seamlessly with conveyor and logistics systems. By reducing manual labor and enhancing safety, this solution boosts operational efficiency and supports smoother inventory flow across your facility.

Transform Your Factory with Smart Robotic Cobot Solutions

Related Products

Get in Touch with Our Automation Experts

Have a project in mind? Let’s turn your ideas into intelligent automation.

Quick Inquiry