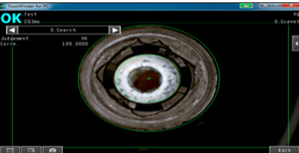

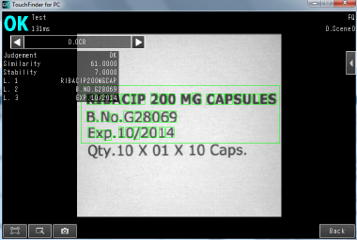

2D inspection is a quality control method that uses two-dimensional imaging to assess and analyze the features of an object or surface. Utilizing cameras and software, this technique captures high-resolution images to detect defects, irregularities, or variations in dimensions and surface quality. It is widely used in manufacturing, electronics, and other industries where precision is critical. By comparing the captured images against predefined standards or models, 2D inspection ensures products meet quality requirements and helps in identifying issues early in the production process.

Categories

COBOT APPLICATION

CUSTOMIZED SOLUTION

ROBOTIC APPLICATION

AUTOMATION SOLUTION

IOT SOLUTION

VISION INSPECTION

Request A Quote

Quick Links

Our Solution

Get In Touch

D-105,106,107, Krish Industrial Park, Vatva Phase-4 GIDC, Ahmedabad 382445

sales@acrobot.in

+91 97255 86288

ACROBOT TECHNOLOGIES 2023-2024 | All Rights Reserved. Design and Developed by Industry Lead -8000121171